Why Does Custom Parquet Veneer Transform Ordinary Spaces Into Masterpieces?

Custom parquet veneer brings timeless elegance to any interior, combining artisanal craftsmanship with modern engineering. But how can you harness this versatile material to create your perfect space? Let’s explore the design possibilities, technical considerations, and installation secrets that make parquet veneer the choice of designers worldwide.

The Parquet Advantage

✔ Unmatched visual depth with 3D wood grain patterns

✔ Engineered stability prevents warping

✔ Endless customization possibilities

✔ Eco-friendly alternative to solid wood

Technical Specifications

| Parameter | Specification |

|---|---|

| Veneer Thickness | 0.6mm – 4mm |

| Panel Sizes | 450x450mm to 600x1200mm |

| Wear Layer | 2-5mm sandable surface |

| Installation Methods | Glue-down, floating, nail-down |

| Surface Treatments | UV lacquer, oil, wax |

Stunning Parquet Patterns to Consider

1. Classic Herringbone

- 45° or 90° installation angles

- Creates dynamic visual movement

- Ideal for traditional and transitional spaces

2. Modern Chevron

- Sharper zigzag pattern than herringbone

- Contemporary aesthetic

- Excellent for elongating small spaces

3. Basket Weave

- Interlocking square pattern

- Adds texture without overwhelming

- Perfect for rustic and farmhouse styles

4. Versailles

- Intricate geometric design

- Makes a bold statement

- Best for large, open areas

5. Custom Mosaics

- Unlimited design potential

- Incorporate multiple wood species

- Create unique brand identities

The Design Process: From Concept to Installation

| Space Analysis | Material Selection | Pattern Engineering | Precision Manufacturing |

| Measure room dimensions Assess lighting conditions Identify focal points |

Choose wood species (oak, walnut, maple) Select grain pattern (plain, quarter, rift sawn) Determine finish type |

Digital rendering of custom designs Prototype sample production Structural integrity testing |

CNC cutting for perfect joints Quality control checks Protective packaging |

Installation Best Practices

🔧 Subfloor Preparation:

- Must be level (≤3mm variance over 2m)

- Moisture content below 12%

- Proper acclimation (72 hours)

⚠ Professional Tips:

- Always start from room center

- Maintain expansion gaps

- Use specialized parquet adhesives

💡 Maintenance Secrets:

- Daily dust mopping

- Avoid excessive water

- Recoat every 3-5 years

Where Does Custom Parquet Shine?

| Residential Applications | Commercial Spaces | Unexpected Uses |

| Feature walls Kitchen islands Stair treads |

Luxury retail stores Hotel lobbies Corporate offices |

Ceiling treatments Furniture tops Artistic installations |

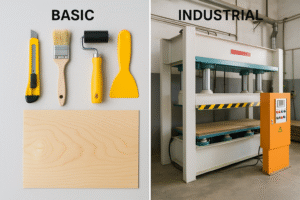

Why Choose Veneer Over Solid Wood Parquet?

- 50-70% cost savings versus solid wood

- Greater stability in varying climates

- More sustainable – 10x coverage per log

- Easier repairs – replace single elements

Customization Options

Most manufacturers offer:

- Laser-cut inlays

- Mixed material designs (wood + metal)

- Custom stains and finishes

- Glow-in-the-dark elements

Final Thoughts

Custom parquet veneer offers limitless possibilities to elevate your space from ordinary to extraordinary. Whether you’re creating a cozy home library or a show-stopping retail environment, the combination of traditional craftsmanship and modern technology delivers breathtaking results.

Ready to design your perfect parquet pattern? Share your space dimensions and style preferences below for expert recommendations!